Aquarium Mechanical Pressurized Filters

MAT Mechanical Pressurized Filters are rapid, pressurized multilayer filters filled in with Glass Filter Media (GFM) instead of sand to double the process performance. The CFM offers 300 times more surface area than the sand media, is electrostatically charged to absorb organic substances and small particles and finally the metal oxide catalysts located on its surface make the glass media self-sterilizing, as well. The developed filtration speed varies between 20 – 25 m/h at a pressure rate of 2.5 bar. The specific filter configuration offers extra resistance to bio-fouling, to bio-coagulation and does not permit any unfiltered water to escape due to transient wormhole water channeling.

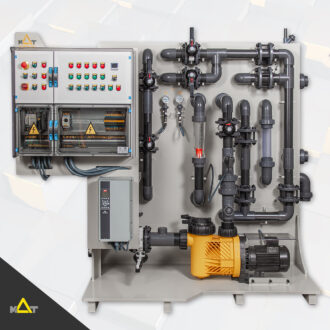

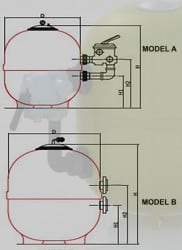

The Mechanical Pressurized Filters may be backwashed by reversing the water delivery to flow from the lower to the higher media layers collecting and discharging the deposited particulate matter to the effluent waste line. The pressurized vessels are made from Bobbin Wound FRP or laminated FRP vessels, vinylester coated offering optimum ozone osmosis protection, pneumatic or motor actuated manifold, manometers and air pressure relief valves.

WHAT IS GFM?

Glass Filter media are bio resistant filtration media made from glassGFM can be manufactured from manufactured from green glass to replace sand in all types of sand filters and all types of water filtration applications.The amorphous aluminosilicate glass proceeds through a patented activation process to increase the surface area by 300 times over sand. The high surface nano – structure area is negatively charged to selectively adsorb organics, priority substances and small particles. The surface also has metal oxide catalysts that give a high redox potential to make the glass media filters self-sterilizing that prevent bacteria mud-balling, coagulation and worm-hole channeling of unfiltered water through the filter bed.

OFFER, USE & APPLICATION OF Mechanical Filters

MAT FILTERS present the solution for optimal and total water filtration at lower power consumption rates when compared to traditional sand filters. The media used allow ease of operation and although a higher initial investment, the ROI is fast.

They are applicable to Aquariums, Aquaculture Facilities, generally to all Wastewater Treatment Applications.

OPERATION & ENGINEERING

The waste water is dispersed evenly over the Activated Filter Media by diffusers which are located on the upper part of the vessel. As the water permeates down through the media layers, the particulate material carried in the water is deposited to the GFM. The GFM are manufactured from amorphous aluminosilicate glass, subjected to form a large nanostructure effective area. The metal oxide catalysts located on the media surface give a high redox potential making GFM media self sterilizing, against undesirable microorganisms.

Glass Filter Media

Glass Filter Media result among others in 30% – 80% improvement than regular sand filter performance by replacing the sand with glass.

Advantages of Pressurized Glass Media Filters

- More than doubled performance over a conventional sand filtration system

- Higher effective filtration surface than sand

- Presents Biodynamic Stability

- Does not permit untreated water escape

- Substantially lower chlorine oxidation demand

- Around 50% lower backwash water need

- Glass media is never changed or replaced

- Glass is a Self-Sterilizing Media

- No bacteria bio-fouling

- No bio-coagulation

- Glass filters optionally, coated for extra ozone osmosis protection, pneumatic or motor actuated manifold, manometers and air relief valves.

- Resistive and durable structure

- Fast ROI R-134a, environmentally friendly gas

- Small footprint

- Automated, smart control of operation

- Oil free compressor elongates the Air Dryer

- Oxygen concentrator Lifetime

- Durable robust design excellent resistance to harsh environment

- CE Certification

- No filter clog

- No need of periodic backwashing

- No problems due to sludge bulking

- Resistive and durable structure

- Low head pressure loss

- Reduced sludge production

- No need of periodic backwashing

- No sludge bulking

- Complete organic load removal

- Compact Unit with increased treating process capacity