AQUARIUM PROTEIN SKIMMERS

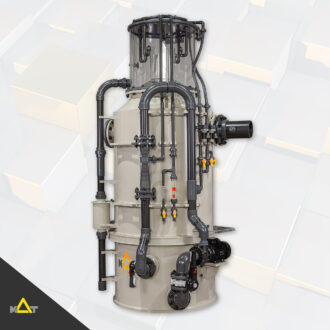

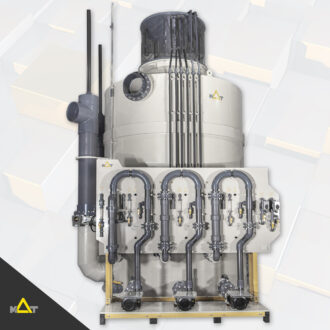

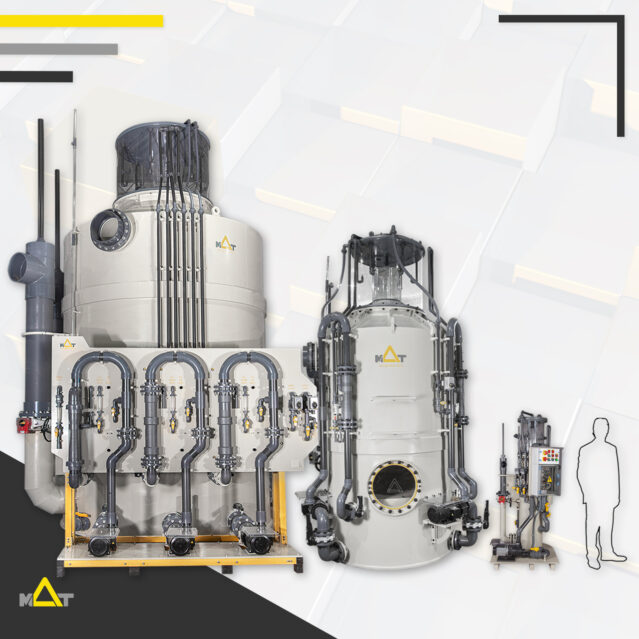

MAT PROTEIN FRACTIONATOR SKIMMERS (PSK) have been designed after many years of testing on high bio load water conditions at our research facility. Designed to provide quality performance, ease of operation & robust fabrication. MAT PSK units manufactured in-house in polyethylene (PE) or polypropylene (PP) plastic, by SIMONA A.G. MAT PSK come in a variety of standard sizes and can be customized to suit any facility size and flow parameters.

MAT PSK units competitive advantage is the quality fabrication & the ease of operation. PSK units carry MAT & uniquely engineered Venturi, infusing the correctly balanced amount of Oxygen and Ozone inside the PS body, achieving maximum saturation of Ozone in the treated water. Furthermore, the PSK & internal design is made in such a way as to create & retain the finest air bubbles up to the skimmer cup. This process results in maximum performance, producing a bio/ protein waste that is significantly thicker than industry standard.

Our Protein Skimmer units are not & temperamental & in their operation; therefore, there is no need for constant fine adjustment once the PSK is commissioned. MAT PSK units, optionally, arrive with sludge Auto Wash System, allowing the outer cap to be rinsed with fresh water and the inner neck rinsed with system water minimizing the loss of water. MAT PSK units may be manufactured upon request to operate with fresh water. MAT PSK come with a pre-fitted IP67 electrical switch board in line with the most stringent safety regulations. All components and materials are rated to operate under high salinity & humidity condensed environments.

OFFER, USE & APPLICATION OF AQUARIUM SKIMMERS

MAT Protein Skimmers are used to provide an efficient means of floatable and dissolved solids control, by removing mechanically, fine and dissolved organics from water. Additionally, through the fractionation process, MAT PSK minimize Bacteria & microorganisms concentration in Close Circuit Life Support Systems (CC-LSS).

Our Protein Skimmers are core elements in any traditional LSS, and are complementary to pressurized sand filters, paper filters, algae scrappers, moving bed filters, cartridge filters, drum filters and trickle filters.

OPERATION & ENGINEERING

MAT Protein Skimmer operation is based on the Centrifugal mechanical removal of organic compounds. MAT PSK optimize operation is through ozonized air which is injected into the treated water, as a stream of fine bubbles, by a low pressure venturi set. As the bubbles rise up through the water column, proteins and other surface active compounds are attracted to each other. The organic coat/ bio sludge is clogged in fine bubbles as they rise up through the water column. This foam is ejected from the protein skimmer through the effluent pipe and is discharged to the sewer or the backwash treatment. An important secondary effect of protein skimming is the removal of fine particulate material (<40 micron) that attaches to the foam.

Protein Skimmer TechnologyADVANTAGES OF MAT PROTEIN SKIMMERS

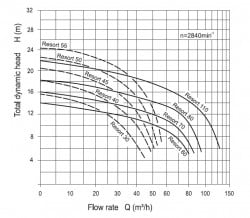

MAT Protein Skimmer Filtration Systems remove mechanically 90% of the dissolved organics, proteins, fish food remains and tints from the water column Removal of fine particulate material (<40 micron) that attaches to the foam Reduced load imposed on the pressure sand filters, allows a higher filtration velocity through them Maximize oxygen saturation in the water while it mixes and dissolves oxygen and ozone. Control and monitoring of ozone dosing by ORP probe as part of the water quality monitoring package Auto-wash system for inner and for outer tube. Resistant and robust fabrication Easy foam level fine tuning Custom made sizes Protein Skimmers are also available.